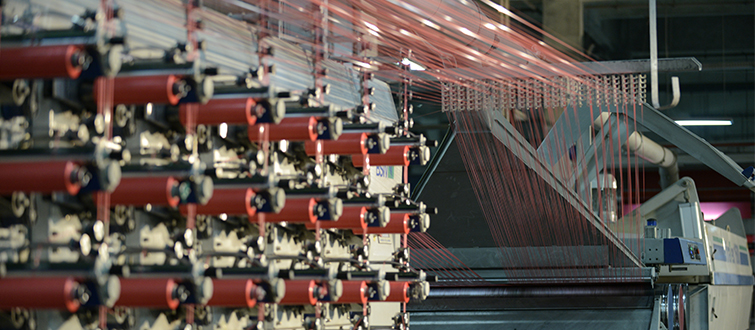

High-tenacity polypropylene technical fibers are produced as starting material for additional processing in the fields of ropes, webbing and sewing threads. For their parameters they are in great demand by manufacturers of nets and filter cloths. Sewing threads and woven webbing are made by us for own needs as well as for our clients from various sectors of the textile industry. The quality management system according to ISO 9001 is a prerequisite to realization of deliveries to the majority of our clients.

We offer a wide choice of colors . especially for the high-tenacity polypropylene fibers and webbing made of them. PP multi filament fibers, sewing threads and webbing are made of hygienically safe materials and are certified as hygienically safe. Polypropylene is a fully recyclable material and does not burden the environment.

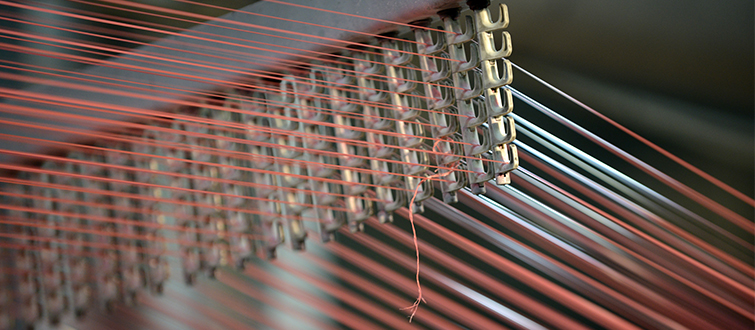

We manufacture our polypropylene sewing threads in different linear densities and in basic colors.

Our sewing threads have an odorless, non-toxic surface treatment that is not hazardous to health. This allows the threads to be sewn quickly, without damaging the thread structure by friction (with resulting high temperature). Products sewn with these threads can be used in a wide variety of industrial applications where hygiene is of the utmost importance, especially in the food, pharmaceutical and chemical industries.

The sewing threads are used primarily for polypropylene fabric sewing. They are noted for high strength and elongation which provide for the necessary properties of the seam even under high load.

Sewing threads made by Al Ahram are supplied on paper tubes as cylindrical spools with a total weight of 3.5-4 kg. The spools are wrapped up in PE or PP bags, which guarantees a constant quality during the entire storage period. The spools are shipped in boxes .